Keeping Your Hands Safe

Keeping Your Hands Safe

Hands are the most susceptible to accidents and injuries during work. These are most often minor lacerations, cuts and abrasions, but sometimes more serious injuries can also occur. An easy prevention solution is work and protective gloves, which reduce the risk of hand injuries by up to 60%. Gloves belong to the basic equipment of all professions and do-it-yourselfers and gardeners. However, there are different types of gloves made from different materials, so it is not difficult to get lost in the wide range. Read what to follow when choosing suitable gloves, what properties each material has and what the standards tell you.

Factors to Consider

Factors to Consider

One of the paramount factors in choosing the right gloves is identifying the specific risks involved in your work. Whether dealing with sharp objects, hot materials, or hazardous chemicals, different gloves cater to distinct needs. Following industry standards is crucial in ensuring the gloves' efficacy. Consider the glove's length, cut, cuff style, and overall construction, as well as the materials used. Additionally, factor in the level of workload, as it impacts the longevity of your chosen solution. Specific considerations, such as latex and silicone-free options for allergy sufferers or anti-static gloves for certain environments, add another layer to the decision-making process.

It's essential to ensure that the chosen gloves do not impede movement, compromise fine motor skills, or weaken your grip's strength and precision. Inadequate anti-slip properties can lead to accidents, especially when handling sharp objects in wet or greasy conditions, posing a risk of cuts to workers' hands. Comfort is equally crucial; uncomfortable gloves may prompt workers to remove them, exposing their hands unnecessarily.Convenience also plays a role. Gloves that are uncomfortable to wear will be taken off more often by the worker, unnecessarily exposing his hands to danger.

At CERVA, we offer a range of high-quality and comfortable gloves crafted from different materials. These gloves provide protection against mechanical risks, cuts, thermal hazards, chemical contamination, and special risks like electric shock or high voltage. In the following sections, we'll guide you on choosing gloves tailored to your specific activities.

| Size | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| Palm circumference [mm] | 152 | 178 | 203 | 229 | 254 | 279 | 304 |

| Seamless glove cuff color | pink | white | green | grey | yellow | brown | black |

Handling Light Objects Without Sharp Edges

Handling Light Objects Without Sharp Edges

Are you moving, working in a warehouse and in logistics, replenishing goods or perhaps light construction work? Soaked gloves (in polyurethane, PVC or latex) will protect your hands well . You don't have to worry about dirt or scratches. In addition, these gloves fit perfectly and do not restrict you in any way. Gloves dipped in nitrile are an ideal choice for handling slippery objects.

Another option is combined gloves (most often made of leather and cotton), which are suitable for handling heavier loads and come in handy for road workers, builders, repairmen and workers in agriculture, metalworking and other industries.

Working with Sharp Objects

Working with Sharp Objects

If you handle cutting tools, glass, sheet metal or perhaps branches, choose gloves that protect against cuts and punctures. The aramid fiber provides them with anti-cutting properties and high resistance . For the safety of the whole arm, complement them with an anti-cut sleeve.

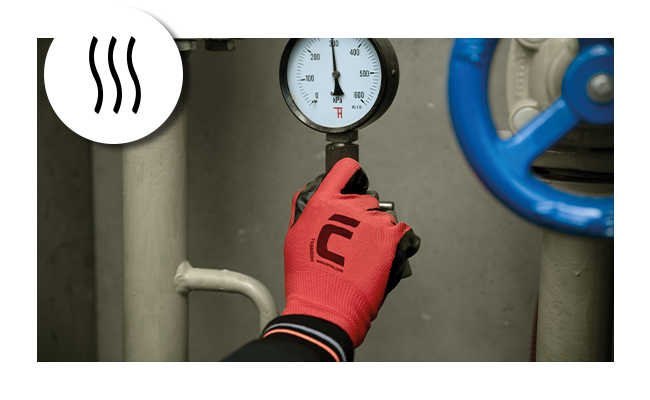

Working with Hot Objects

Working with Hot Objects

Welders and casters are not the only ones who need to protect themselves from burns. Thermal hazards occur in many workplaces and in various fields. Gloves with aramid fiber again protect well against radiant and contact heat and red-hot metal . Leather and latex also have heat-insulating properties. Heat-resistant work gloves are produced in different degrees of resistance. So when choosing, take into account how high a temperature they should protect against and for how long.

Special welding gloves are intended for welders, which are longer and cover the forearm as well. Choose them according to the welding method (TIG, CO2, MMA)

Working with Dangerous Chemicals

Working with Dangerous Chemicals

Gloves that protect against chemical risks are divided into disposable and chemically resistant, which are intended for repeated use. Chemical resistant gloves are produced in different lengths to protect not only the hands and palms, but also the wrists and forearms. Even in this category, you can choose different degrees of resistance – type A provides the highest protection (protects against at least six different chemicals for a period of more than 30 minutes), and type C provides the lowest.

Rely on the standards

You can also follow the standards when choosing work gloves.

EN 388

EN 388

You will most often encounter the EN 388 standard - Protective gloves against mechanical risks. It is supplemented by 6 numbers:

- The first number assesses abrasion resistance on a scale of 1-4 (the higher the number, the higher the resistance)

- The second number describes the blade cut resistance on a scale of 1-5. If you see an x in the second position instead of a number, it means that the edge was blunted during the test.

- The third digit means tear resistance on a scale of 1-4.

- The fourth position refers to puncture resistance 1-4.

- The fifth digit determines the cut resistance of the glove in a test according to EN ISO 13977. Every glove that has previously dulled the test blade must pass this test. The result is given in the letters AF (F stands for highest protection)

- And the last position assesses impact resistance . A glove that passes the test is labeled P. If you don't find the sixth digit, the glove either failed the test or was not relevant.

If there is an X in place of the number in any of the six positions, it means that the glove failed the test or the test does not apply to the selected model.

EN 407

EN 407

Another useful standard is EN 407 – Protective gloves against thermal risks (heat and/or fire). Here, too, the pictogram is supplemented by six numbers (or the letter x) depending on the type of heat risk the gloves protect against. A scale of 1-4 is used for all risks, where 4 means the highest level of protection.

- A: fire behavior (flame and heat) If the number is lower than 3, the glove fails the other tests as well.

- B: contact heat (contact and boundary temperature)

- C: convective heat (delayed heat transfer) D: radiant heat (delayed heat transfer) E: small drops of molten metal F: large amount of molten metal

EN 511

EN 511

In freezing weather or refrigerated spaces, it is important to protect your hands from the cold. Choose those that have passed the tests of the EN 511 standard - Against the cold (up to -50 °C). The additional numbers again determine the risk against which the gloves protect:

- A: Resistance to Convective Cold (0-4)

- B: Resistance to contact cold (0-4)

- C: Water permeability (0 = glove does not protect against water penetration; 1 = glove is waterproof)

EN 374

EN 374

Gloves that protect against dangerous chemicals and microorganisms meet the EN 374 standard . Both the chemicals they protect against and the time after which the gloves do not leak chemicals are tested.

- Type A: protects against at least 6 listed chemicals (more than 30 minutes)

- Type B: protects against at least 3 listed chemicals (more than 30 minutes)

- Type C: protects against one listed chemical (more than 10 minutes)

EN 12477

EN 12477

Gloves for welders are marked by the EN 12477 standard , which ensures protection against high temperatures and hot metal.

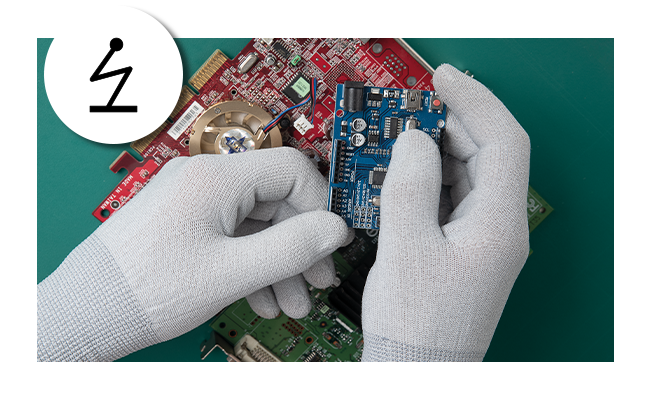

EN 1149-5 a EN 16350

EN 1149-5 a EN 16350

Gloves intended for work under voltage have the EN 1149-5 standard.

EN 16350 - the antistatic gloves are designed to prevent the buildup and discharge of static electricity, making them suitable for environments where electrostatic-sensitive devices (ESD) or materials are present. Antistatic gloves are typically used in electronics manufacturing, cleanrooms, server rooms and data centers, laboratories, telecomunications, flight avionics etc.

EN 10819

EN 10819

These gloves are designed for individuals who work with hand-held vibrating tools or machinery, such as jackhammers, chainsaws, or other equipment that generates hand-arm vibration. These gloves aim to mitigate the risk of hand-arm vibration syndrome (HAVS) or other related health issues caused by prolonged exposure to vibrations.