Fallgefahr

Fallgefahr

Obwohl Absturzsicherungen an vielen Arbeitsplätzen vorgeschrieben sind, werden sie oft vernachlässigt, und die Absturzgefahr wird auf die leichte Schulter genommen. Sie sollte jedoch nicht unterschätzt werden, denn sie ist die dritthäufigste Ursache für tödliche Arbeitsunfälle. Gehen Sie mit uns die einfachen Zahlen durch: Die Reaktionszeit eines Menschen auf ein unerwartetes Ereignis beträgt etwa zwei Sekunden. In dieser Zeit stürzt eine Person fast 20 Meter in die Tiefe und erreicht eine Geschwindigkeit von 71 km/h. Kurz gesagt, es genügt ein kleines Zögern oder ein Moment der Unachtsamkeit, und schon kann ein Unglück passieren. Lesen Sie, wie wir gemeinsam die Sturzgefahr deutlich verringern können.

Wann ist eine Absturzsicherung erforderlich?

Wann ist eine Absturzsicherung erforderlich?

Absturzsicherungen sind erforderlich, wenn die Gefahr besteht, dass Arbeitnehmer aus der Höhe fallen, sei es durch Auf- oder Abwärtsbewegungen. Die OSHA schreibt vor, dass Absturzsicherungen an Arbeitsplätzen in der allgemeinen Industrie in einer Höhe von vier Fuß, in Werften in einer Höhe von fünf Fuß, im Baugewerbe in einer Höhe von sechs Fuß und in Langgutbetrieben in einer Höhe von acht Fuß vorhanden sein müssen. Darüber hinaus schreibt die OSHA vor, dass bei Arbeiten über Wasser oder über gefährlichen Stoffen, Geräten und Maschinen unabhängig von der Absturzhöhe eine Absturzsicherung vorhanden sein muss.

Leitplanken- und Sicherheitsnetzsysteme

Leitplanken- und Sicherheitsnetzsysteme

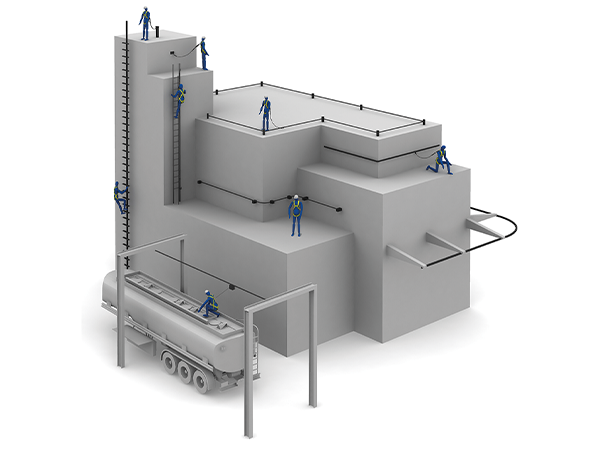

Wir bieten den Entwurf, die Installation, die Wartung und die Revision von festen Sicherheitssystemen an: Schutzvorrichtungen, die einen Absturz vollständig verhindern, wie z. B. Geländer, Laufstege und Übergänge auf Dächern oder Luken über dem Boden, die den Arbeiter im Falle eines Sturzes rechtzeitig auffangen - Fanggerüste, Geländer oder Netze. Wir konzipieren diese Systeme immer für eine bestimmte Situation und installieren sie dauerhaft an Gebäuden oder Bauwerken.

Wenn Sie Interesse haben, wenden Sie sich bitte an unsere Vertriebsmitarbeiter. Unser Techniker kommt zu Ihnen vor Ort und findet gemeinsam mit Ihnen die beste Lösung für eine sichere Arbeitsleistung.

Die Systeme sind nach den Normen EN795 und EN353-1 zertifiziert

An Orten, an denen eine Schutzvorrichtung nicht installiert werden kann, ist ein Sicherheitsnetz oft die beste Lösung. Wir verkaufen, vermieten und installieren Sicherheitsnetze. Wir liefern und montieren sie nach der Norm EN 1263-1. Wenn Sie Interesse haben, wenden Sie sich bitte an unseren Vertriebsmitarbeiter.

Grundlagen des Arbeitens in der Höhe

Grundlagen des Arbeitens in der Höhe

Die grundlegenden Bestandteile der Absturzsicherung werden durch das ABC-System beschrieben:

- A: Verankerung

- B: Körper (Gurtzeug)

- C: Verbindung

Das System funktioniert nur, sobald ein Teil fehlt, kann es nicht verwendet werden.

A - Verankerungspunkt / Verankerungsausrüstung

Der Ankerpunkt kann ein Profilträger, ein Gerüst, ein Balken oder ein anderer struktureller Punkt sein. Die installierten Anschlagpunkte sind in der Regel mit einer bestimmten Farbe gekennzeichnet. Verwenden Sie keine nicht zertifizierten Anschlagpunkte. Verwenden Sie niemals Stellen mit unbekannter oder fragwürdiger Tragfähigkeit für die Verankerung!

Anschlageinrichtungen können dauerhaft (horizontale oder vertikale Seil- oder Schienensysteme, fest installierte Anschlagpunkte) oder nur vorübergehend (Ankerschlaufen oder -seile, Metallstreben, Gerüstösen, tragbare Gurtsysteme, Metallklammern usw.) angebracht werden.

B - Körpergeschirr

Der Auffanggurt für den ganzen Körper wird zur Vermeidung von Absturzgefahren, zur Arbeitspositionierung oder für Arbeiten an einem Seil verwendet.

Alle unsere Auffanggurte entsprechen den europäischen Normen für die Absturzsicherung. Sie unterscheiden sich durch zusätzliche Funktionen oder Elemente, die den Benutzerkomfort erhöhen, wie z. B. Schnellverschlussschnallen oder Gurtpolsterung.

Der Positionierungsgurt dient dazu, das Betreten von sturzgefährdeten Bereichen zu verhindern. Er ersetzt jedoch nicht den Rückhaltegurt.

C - Verbindungsmittel (Seil mit Stoßdämpfer, selbstaufrollende Vorrichtung oder Positionierungsmittel)

Sie werden als Zwischenglied zwischen dem Auffanggurt des Arbeitnehmers und der Anschlageinrichtung verwendet. Dies ist zum Beispiel ein Falldämpfer mit Seil oder ein Höhensicherungsgerät.

Es gibt zwei Arten von Verschlüssen:

- Rückhaltesysteme - Rückhaltesysteme für Absturzsicherungen schützen die Arbeitnehmer davor, eine potenzielle Absturzgefahr zu erreichen, indem sie ihre Nähe zu dieser Gefahr einschränken. Diese Systeme eliminieren die Möglichkeit eines Sturzes, indem sie die Arbeitnehmer so festbinden, dass sie physisch nicht abstürzen können. Absturzsicherungssysteme sind nicht dazu gedacht, Sie so zu positionieren oder festzuhalten, dass Sie freihändig arbeiten können.

- ein Auffanggerät mindert die Folgen eines Sturzes. Auffangsysteme unterscheiden sich von Rückhaltesystemen dadurch, dass sie Sie schützen, wenn Sie bereits im Begriff sind zu fallen.

Gut zu wissen

Gut zu wissen

Ein wichtiger Bestandteil des gesamten Systems zur Verwendung von Schutzausrüstung gegen Absturz ist ein Evakuierungs- und Rettungsplan. Jeder Arbeitnehmer und jede verantwortliche Person, die Arbeiten in der Höhe beaufsichtigt, muss mit diesem Plan vertraut sein.

Befolgen Sie die Grundsätze der sicheren Benutzung von Absturzsicherungen und die Regeln für Arbeiten in der Höhe. Überprüfen Sie vor jeder Benutzung von Absturzsicherungen, dass diese in einwandfreiem Zustand sind.

Kein Produkt darf Anzeichen einer Beschädigung aufweisen oder einen Defekt haben, der seine Funktion beeinträchtigt.

Befolgen Sie bei der Verwendung von Absturzsicherungen die Gebrauchsanweisung des Herstellers.

Jedes der genannten Mittel unterliegt einer regelmäßigen Revisionskontrolle, und zwar alle 12 Monate ab der ersten Verwendung. Die Lebensdauer dieser Produkte wird vom Hersteller in der Gebrauchsanweisung angegeben.

Brandneuer Katalog FALLSCHUTZ

Brandneuer Katalog FALLSCHUTZ

Informieren Sie sich über unsere Absturzsicherungsprodukte und effektive Lösungen in unserem neuen Katalog. Wir erweitern ständig unsere Produktpalette, so dass Sie nicht nur jahrelang bewährte Bestseller, sondern auch brandneue Produkte finden werden.